Product Description:

Fused Aluminum Oxide is a high-quality abrasive material widely used in various industrial applications due to its exceptional properties and performance. This product is primarily composed of aluminum oxide, a material known for its hardness and durability. Fused Aluminum Oxide is characterized by its high electrical resistivity, making it an excellent choice for applications where electrical insulation is crucial. Its unique combination of physical and chemical properties ensures optimal performance in demanding environments.

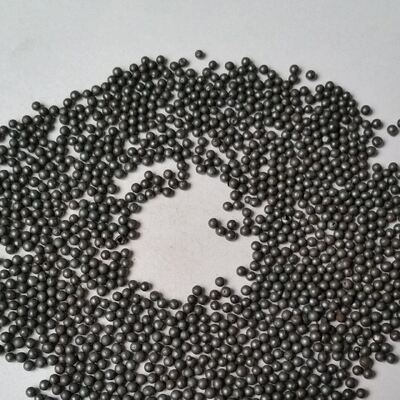

One of the defining features of Fused Aluminum Oxide is its refractive index of 1.76, which contributes to its stability and effectiveness in optical and abrasive applications. The material typically exhibits a color range from white to gray, providing versatility in its use across different industries. This color variation is a natural outcome of the manufacturing process and the specific blend of raw materials used.

As a blasting media, Fused Aluminum Oxide offers superior performance compared to many other abrasive materials. Its hardness and toughness allow it to efficiently clean, etch, and prepare surfaces without causing undue damage. The sharp, angular particles of this product ensure effective material removal and surface profiling, which is essential for preparing metals, ceramics, and composites for subsequent finishing processes.

In comparison to other abrasive grains such as Brown Corundum, Fused Aluminum Oxide provides distinct advantages. While Brown Corundum is known for its toughness and abrasive qualities, Fused Aluminum Oxide boasts higher purity and enhanced electrical resistivity. This makes it particularly suitable for applications where contamination and electrical conductivity must be minimized. It is worth noting that Brown Corundum is often mentioned in the same contexts as Fused Aluminum Oxide due to their complementary properties, but they serve different specific purposes within the realm of abrasive materials.

The high electrical resistivity of Fused Aluminum Oxide makes it an ideal material in electrical insulators and components requiring non-conductive abrasive media. This property ensures that when used in processes like sandblasting or grinding, the material does not interfere with electrical systems or components. Additionally, the refractive index of 1.76 contributes to its optical properties, which can be beneficial in certain specialized industrial applications.

Fused Aluminum Oxide is manufactured through a high-temperature fusion process, which results in a dense, hard, and sharp-edged abrasive grain. This process differentiates it from other alumina-based abrasives, including Brown Corundum, which is typically produced through calcination. The fusion process enhances the product's strength and sharpness, making it highly effective for blasting, grinding, and polishing operations.

The versatility of Fused Aluminum Oxide extends to various sectors, including metal fabrication, automotive, aerospace, and electronics. Its abrasive qualities enable efficient surface preparation, rust removal, paint stripping, and finishing, while its high electrical resistivity and purity ensure safe use in sensitive environments. The color range from white to gray also helps users identify the product easily and select the appropriate grade for their specific needs.

In summary, Fused Aluminum Oxide stands out as a premium blasting media with a combination of high electrical resistivity, a refractive index of 1.76, and the inherent strength of aluminum oxide material. Its white to gray coloration, sharp angular particles, and superior abrasive properties make it an indispensable component in industrial surface treatment processes. While Brown Corundum is frequently cited alongside Fused Aluminum Oxide due to their related applications, the unique attributes of this product, especially its electrical and optical characteristics, provide distinct advantages that enhance performance and reliability in demanding industrial contexts.

Features:

-

Product Name: Fused Aluminum Oxide

-

Chemical Stability: Stable in acidic and alkaline environments

-

Mohs Hardness: 9

-

Color: White to gray

-

Electrical Resistivity: High electrical resistivity

-

Application: Ideal for precision casting products

-

Also known as Fused Alumina and Brown Corundum

-

Excellent durability and performance as Fused Aluminum Oxides

Technical Parameters:

|

Product Name

|

Fused Aluminum Oxide

|

|

Main Material

|

Aluminum Oxide

|

|

Chemical Formula

|

Al2O3

|

|

Density

|

3.95 G/cm³

|

|

Chemical Stability

|

Stable In Acidic And Alkaline Environments

|

|

Appearance

|

White To Gray Crystalline Powder

|

|

Hardness (Mohs)

|

9

|

|

Material

|

Aluminum Oxide

|

|

For

|

Precision Casting Products

|

Applications:

The KMN brand Fused Aluminum Oxide, model number F, is a high-quality blasting media renowned for its exceptional performance and reliability. Certified under ISO 9001, this product ensures consistent quality and meets rigorous industry standards. With a supply ability of 30,000 tons per year and a minimum order quantity of 5 tons, KMN's Fused Aluminum Oxide offers a flexible and scalable solution for various industrial applications. Pricing is negotiable depending on order volume, and delivery times are arranged according to the quantity ordered. Payment terms include T/T and L/C at sight, facilitating smooth and secure transactions.

Fused Aluminum Oxide, also known as Fused Alumina or Brown Corundum, is widely used in precision casting products due to its superior chemical stability and abrasive properties. Its stable nature in both acidic and alkaline environments makes it an ideal choice for applications requiring durability and resistance to chemical wear. The appearance of this product ranges from white to gray crystalline powder, reflecting its purity and effectiveness as an abrasive material.

In terms of application occasions and scenarios, KMN's Fused Aluminum Oxide is commonly employed in surface preparation tasks such as cleaning, deburring, and finishing of metal parts. It is particularly effective in precision casting industries where high-quality surface treatment is critical to ensure the integrity and performance of cast components. The abrasive properties of Fused Alumina enable efficient removal of scale, rust, and other surface impurities without damaging the base material.

Additionally, this blasting media is used in the manufacturing of grinding wheels, sandpapers, and other abrasive tools. Its hardness and sharp edges make it suitable for grinding, polishing, and cutting applications, contributing to enhanced productivity and superior finish quality. The chemical stability of Brown Corundum also allows it to be used in environments where exposure to corrosive substances is frequent, ensuring longevity and consistent performance.

KMN's Fused Aluminum Oxide is also favored in the aerospace, automotive, and electronics industries where precision and reliability are paramount. Whether it is for surface treatment of engine components, mold cleaning, or electronic parts finishing, Fused Alumina provides an efficient and cost-effective solution. The product’s versatility ensures it can be adapted to various blasting equipment and techniques, making it a preferred choice for manufacturers seeking high performance and quality assurance.

In summary, KMN’s Fused Aluminum Oxide (Fused Alumina, Brown Corundum) is an indispensable material for a wide range of industrial applications, especially in precision casting products. Its excellent abrasive qualities, chemical stability, and customizable order options make it an ideal blasting media for industries aiming for superior surface quality and durability.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!